Author:Kai-Yi, Li,National Taichung University of Science and Technology

The experiments were conducted by a semi-automatic dried-longan peeling machine. Four different peeling cams of peeling devices were compared. The radius of curvature of the cam was changed from 40 mm to 50 mm, 55 mm, and 60 mm. The results showed that the speed of peeling devices will decrease as the radius of the outer edge of the cam becomes larger, thereby increasing the peeling success rate.

Longan is one of Taiwan's important economic agricultural products. According to the 107 Agricultural Statistics Annual Report, the planting area of longan is 10,975 hectares and the yield is nearly 77,198 tons. Longan production areas are mostly located in tropical Asia. The production of Taiwan is only less than China and Thailand. Taiwan is one of the important sources of longan supply in global.

There are many years of fundamental research of semi-automatic dried-longan peeling machine. The machine combined with mechanical structure theory, motor transmission efficiency, metal cutting theory, Hooke's law and chain transmission relationship. Meanwhile, optimizing the productivity of the machine by data that were operated and collected through experiment.

In this study, the previously semi-automatic peeling machine was researched and optimized (Figure 1).Defined five operating areas as input area, cutting area peeling area, deseeding area and collecting area(Figure 2), the operation of peeling machine flow chart(Figure 3)

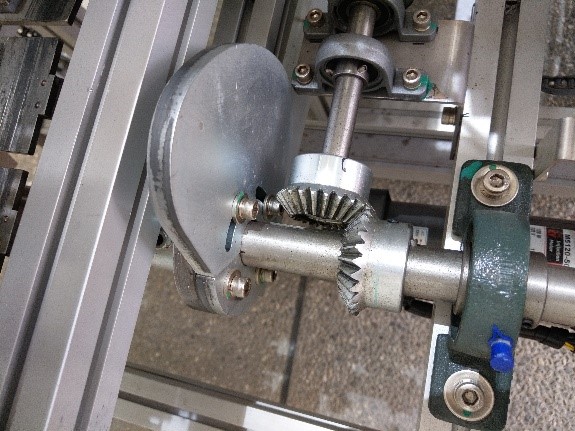

Fig. 4 Peeling cam

Fig. 4 Peeling camThe experiment is mainly to change the cam of the peeling device. The cam will affect the meat peeling speed of the peeling device (as shown in Figure 4), then affect the success rate of peeling. Under the condition of the main motor cycle for 9.38 seconds without changing other parameters, design 3 cams with different outer edges curvature to test their peeling success rate and compare them with origin cam. The outer edge curvature of the cam will change into 40 mm (Figure 5), 50 mm (Figure 6), 55 mm (Figure 7), and 60 mm (Figure 8).

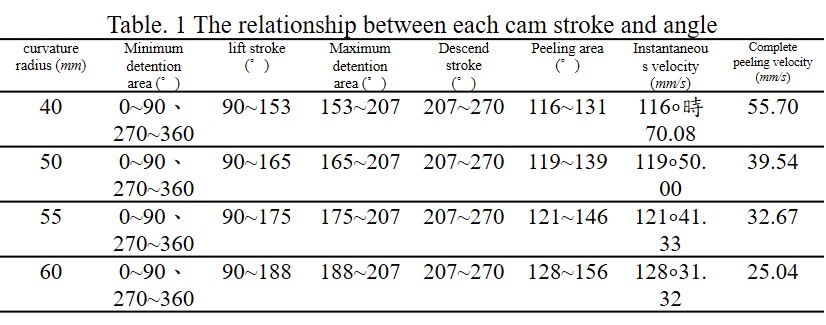

As shown in Table1, the displacement of the peeling device is same to the follower which driven by the cam, the relationship between displacement of the follower and the angle of cam with a curvature of 40 mm, where 0∘~90∘ and 270∘~360∘ are the lowest stroke in the detention zone, 90∘~153∘ is the lift stroke, 153∘~207∘ is the highest stroke of detention zone, 207∘~270∘ is the descending stroke, and the peeling interval is 116∘~131∘, when the cam turns to 116∘, the peeling device start peeling, and its instantaneous speed is 70.08 mm/s, complete The speed of peeling is 55.70 mm/s; the relationship between displacement of the follower and the angle of cam with a curvature of 50 mm, where 0∘~90∘ and 270∘~360∘ are the lowest stroke in the detention zone, 90∘~165∘ is the lift stroke, 165∘~207∘ is the highest stroke of detention zone, 207∘~270∘ is the descending stroke, and the peeling interval is 119∘~139∘, when the cam turns to 119∘, the peeling device start peeling, and its instantaneous speed is 50.00 mm/s, complete The speed of peeling is 39.54 mm/s; the relationship between displacement of the follower and the angle of cam with a curvature of 55 mm, where 0∘~90∘ and 270∘~360∘ are the lowest stroke in the detention zone, 90∘~175∘ is the lift stroke, 175∘~207∘ is the highest stroke of detention zone, 207∘~270∘ is the descending stroke, and the peeling interval is 121∘~146∘, when the cam turns to 121∘, the peeling device start peeling, and its instantaneous speed is 41.33 mm/s, complete The speed of peeling is 32.67 mm/s; the relationship between displacement of the follower and the angle of cam with a curvature of 60 mm, where 0∘~90∘ and 270∘~360∘ are the lowest stroke in the detention zone, 90∘~188∘ is the lift stroke, 188∘~207∘ is the highest stroke of detention zone, 207∘~270∘ is the descending stroke, and the peeling interval is 128∘~156∘, when the cam turns to 128∘, the peeling device start peeling, and its instantaneous speed is 31.32 mm/s, complete The speed of peeling is 25.04 mm/s.

As shown in Table 2, When the speed of peeling motor is 6.4 rpm, the productivity of the machine is 1.07 pieces/sec. The cam with the outer edge radius of 55 mm with the highest peeling success rate selected and its peeling speed is 32.67 mm/s. As shown in Table 3, if the productivity of the machine increase to 1.5 pieces per second, the speed of the power peeling motor would be 8.99 rpm. As the speed of the main motor increases, the speed of the peeling speed increases, and the speed of the peeling is 44.71 mm/s. It is faster than the best peeling speed of 32.67 mm/s. Therefore, it needs to replace the larger radius cam to reduce the peeling speed for achieving a better peeling speed.

Changing the ascending speed of the peeling device through changing the outer edge of the peeling cam. The success rate of peeling can be improved; Increase appropriately the speed of the peeling motor and choose the appropriate peeling cam are able to improve the machine productivity.