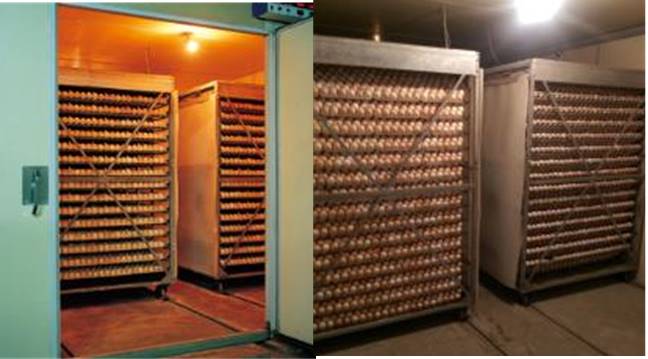

Figure 1 Continuous egg incubator

Figure 1 Continuous egg incubatorAccording to the results of the agricultural statistical annual report published by the Council of Agriculture, Executive Yuan in 2016, about 370 million fowls were slaughtered in 2016. The domestic demand for chicken is extremely high. Since chickens are hatched from eggs, how to effectively increase the hatching rate is an important topic. The hatching rate of most domestic hatcheries is low, which directly affects the income of the operators and indirectly affects the market demand. Therefore, our R&D team have developed the “Intelligent Continuous Incubation System” and implemented it in the hatchery of Kaixin Industrial Co., Ltd. Advanced technologies, such as sensing technology, intelligent machine equipment and big data analysis are adapted to analyze the cause of low hatching rate so that effective preventive measures can be taken timely to improve hatching efficiency.

Figure 2 Tilted egg pans

Figure 2 Tilted egg pansAfter the eggs are transported from the breeder farm to the hatchery, they are placed in the incubator (Figure 1). The egg trays are tilted at 45 degrees (Figure 2), and are rotated automatically at a regular interval to prevent the adhesion between the embryo and shell membrane so that all parts of the embryo are evenly heated. Fresh air is supplied to facilitate embryo movement and keep the fetuses at the right position for smooth hatch. The whole incubation process takes 18 days, and then the eggs are transferred to another machine for hatching. Three days later, the eggs will hatch out.

It was necessary to manually monitor the environmental condition of the incubator at all times during the incubation process. With the intelligent continuous incubation system, the temperature, humidity and ventilation can be monitored at all times through sensors, and the incubation environment can be kept at the optimum level by adjusting the ventilation facility through the control system. The environment monitoring app can instantly notify the operator so that the operator can keep track of the environment in the incubation room. The data can also be instantaneously transmitted to the decision-making support system in the head office by the Cloud platform. After the introduction of the intelligent continuous incubation system, the hatching rate can be increased from 86~89% to 90~93%. The system can not only reduce the manpower required for patrolling the hatcheries but also incubate 100,000 eggs at a time. It is indeed an intelligent device with scale.

The intelligent continuous incubation system contains five operation modes: automatic mode, manual mode, warning mode, parameter setting mode, and time setting mode, and four display areas for setting environmental parameters, as shown in Figure 3. Temperature and humidity values are set at the main temperature and humidity display control area, and the upper and lower limits can be set in the area below. When the value is higher than the upper limit or lower than the lower limit, the system will automatically start to regulate the temperature and humidity of the environment. The abnormal status display area will automatically send a warning when abnormalities are identified. The hatching control display area shows the status of the fans, heaters and other controllers in the incubation room. The egg rotation control area displays the egg rotation time, remaining time and the rotating direction. By pressing the start button, the operator can force the egg rotation. Temperature, humidity, ventilation and other parameters in the incubation room are recorded every minute, and are plotted to show the temperature and humidity curves, as shown in Figure 4. The data are transmitted to the network platform for determining the best environmental parameters for egg incubation by big data analysis so that each egg can be incubated in the best environment set by the intelligent continuous incubation system.

▲Figure 3 Man-machine interface for intelligent continuous incubation system |

▲Figure 4 Temperature and humidity graph of the incubation room

|