Author:CHANG KUANG-HUA, TSAI PING-YUN and CHIEN HUNG-YU,Hualien District Agricultural Research and Extension Station, Council of Agriculture,Executive Yuan

I. Preface

Under the Big Granary Project and the organic friendly policy of the Council of Agriculture (COA), this Station has been actively engaged in the R&D of agricultural machinery of adequate operational capabilities and reasonable prices for the farming industry. The latest product developed is the "Hanging Type Weeder for Ridge Cultivation", a weeding machine suitable for dry field crops grown on double rows with one single furrow.

Organic cultivation accounts for more than half of the 300 hectares of soybean plantation in Hualien. The types of planting beds for soybean can be either culture without ridging or ridging culture. Ridge culture is usually adopted for the advantage of easy drainage in heavy rainfall and furrow irrigation during water shortage. Level culture, however, with the wider space between the planting beds, means better ventilation, lower chance of pests and diseases, and easy access by vehicles for weeding operation. In the past, due to the small unit space area of the organic soybean plantations and the absence of suitable inter-row weeding machine, we mainly promoted level culture and suggested weeding by ordinary cultivators. As the cultivated area increased, we developed the ride-on "Hanging Type Weeder for Ridge Cultivation” in 2018 to raise the efficiency of mechanical weeding.

However, as ridge culture has been the major practice for soybean cultivation in Taiwan, and peanuts are also grown in the similar manner of single furrow between parallel planting beds, with a total area of nearly 30,000 hectares, we find it necessary to develop of the ride-on type of inter-row weeding cultivator for promotion of organic soybean and peanut planting.

II. R&D of Weeding Machines for Ridge Culture

There are two types of weeding machines for ridge culture planting: the rotary blade and the disc plow. These weeding machines are usually imported from Niplo and Iseki in Japan. The rotary tiller type is powered by the tractor power to trim the topsoil and remove the weeds. It can cope with various conditions of the weeds and soil textures. However, there are spots on the sides of the ridge the weeding machine cannot reach and the blades may be broken by gravels. The disc plow better matches the shape of the ridge, operates better near the bottom and side of the ridge, and can better withstand the impact of gravels. In addition, it has three times the towing efficiency of that of the tiller type. However, both these two types are just for weeding between the furrows, covering less than half of the area that needs to be weeded. The weeding on the surface of the ridge still needs to be done manually.

After discussions with the local farmers, and inspired by previous experience in the development of weeders, we decided to integrate the features of rippers, disc plows, and elastic weeding claws to design two weeder prototypes for weed control. The principle is to first plow the soil to loosen the base of the weeds, and then rake the weeds with the claws or the disk plows. The two-step operation does better in having the weeds wither and removed, so as to substantially raise the control rate.

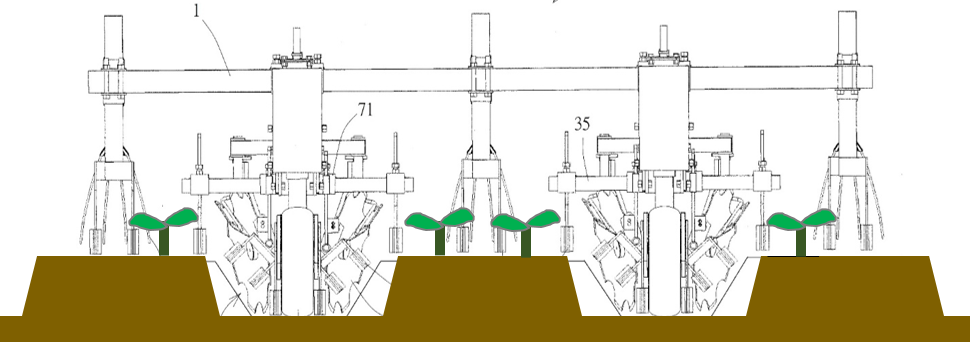

After repeated field tests, the development of the "hanging-type inter-row weeding cultivator" was completed. The machine completely covers the surface, the sides, and the foot of the ridges and can keep away from the plants to achieve a delicate, three-dimensional weeding effect. It adopts a modular design so as to match the specifications of 4-row or 6-row vacuum planters. The damage caused to the weeding cultivators due to the different widths of the staggered planting beds can be minimized.

圖七、新型除草機可完整涵蓋畦表面,達到細膩的中耕除草效果

圖七、新型除草機可完整涵蓋畦表面,達到細膩的中耕除草效果III. Guidance on mechanical weeding for organic soybeans and peanuts

After the completion of the development of the machine, a series of test runs were conducted in the FOUR SEASONS PUREFOOD COMPANY in Shoufeng Township, and the weed control rate of organic soybeans and peanuts was found to be over 90%. A publicity event of mechanical weeding was then held in May, in which demonstration was given on the operation and the tuning of the machine and suggestions were made to select the most suitable types of the machine based on the properties of the plants and the soil, and to take into account the weather conditions when scheduling the weeding. The farmers were also advised to minimize the difficulty of weeding by taking precautionary measures like paddy-upland crop rotations and multiple land preparations to reduce the density of weed seeds in the field. Onsite discussion was open among the participants in the organic peanut field in Xikou Village, Shoufeng Township. Participating farmers gained great interest and confidence in future planting and management after witnessing the success demonstrated.

圖十、簡宏諭助理說明機械結構與操作方法

圖十、簡宏諭助理說明機械結構與操作方法IV. Mechanical performance and cost effect analysis

The inter-row weeding cultivator is attached to the rear of a tractor or rice transplanter. Its operation is convenient and time-saving as it works simultaneously on several planting beds. Its work capacity is 2.5 hectares per day at an average weed control rate of over 90%, and a damage rate of less than 5%. In practice, the factors of the size of the planer, the habits of the operator, and the soil texture all need to be taken into account, and the weeding cultivator we designed can be easily adjusted to meet the actual conditions in operation, including the position, width, depth, range of opening, and inclination of the weeds.

Compared with manual weeding, the control rate of mechanical weeding is slightly lower, but the continuous operation lifts the efficiency by more than 25 times. For every two weeding operations on one hectare, there is a saving of at least 150 farming hours and NT$36,000 of labor costs. Besides, farmers find the machine made in Taiwan more affordable as its price is 50% lower than imported ones.

V. Conclusion

Weed management is a key technique for organic cultivation. In Hualien, where weather conditions are changeable during the spring farming season, inefficient weeding methods often fail to keep up with the growth of weeds in the warm temperature. The development of the "hanging type inter-row weeding cultivator" has met the demand of mechanical weeding for organic soybean cultivation, providing a new option for weed management in organic farms. Farms of customary farming can also choose mechanical weeding to reduce the use of herbicides. The introduction of the new weeding cultivator not only reduces the labor costs, but also supports agricultural policies, such as organic friendliness, reduced use of pesticides, and sustainable agriculture.