Author:Shi, Bo-You/Research Assistant, Intelligent Bio-Sensing Lab, Department of Biomechatronics Engineering, National Taiwan University

Chen, Lin-Chi/Professor, Intelligent Bio-Sensing Lab, Department of Biomechatronics Engineering, National Taiwan University

In the face of global carbon reduction trends and the demand for sustainable agricultural development with net-zero emissions, efficient resource management and reducing environmental pollution have become key goals for global agriculture. Meanwhile, climate change and the COVID-19 pandemic have increased the crisis in traditional agricultural supply. In recent years, Taiwan has been promoting indoor farming, which is regarded as one of the most promising solutions. Hydroponics is the most common indoor farming cultivation method. Because the nutrient solution is the primary source of nutrition for crops in hydroponics, the significant concern in precision agriculture is the need for precise fertilization.

At present, farmers typically adjust nutrient solutions based on plant traits, pH value, and electrical conductivity (EC) value. However, the concentration and ratio of different ions in the nutrient solution can’t be understood by measuring pH and EC values. Several nutrient imbalances lead to similar physiological characteristics. Therefore, if the nutrient ratios are not adjusted appropriately or if the type of nutrient deficiency is misjudged, it results in significant differences in the quality of vegetables. These differences may manifest in various aspects, including weight, leaf size, plant height, color, flavor, and crispness. Currently, farmers need to send samples to testing facilities for nutrient analysis, and it takes approximately one month to receive the data. The waiting time prevents farmers from making immediate adjustments to the nutrient solution. Therefore, a more ideal approach would be the ability to directly and instantly measure the concentration of various ions in the nutrient solution. The common ion sensors available in the market use conventional ion-selective electrodes (ISEs). The advantages of ISEs are that they eliminate the need to send samples to a laboratory and provide rapid measurements. However, each ISE can only measure a single type of ion, and their large size makes integration into automated systems challenging.

The key technology of the IoT nutrient sensor system (IoNSS) is multi-ion arrays based on solid-contact ISEs (SCISEs) due to their small size and ease of integration (Taiwan patent number I517989, 2016). During the development, a portable multi-ion sensing device is first integrated with a multi-ion array and a multi-channel module allowing it to simultaneously measure eight ion concentrations (Taiwan patent number I695166, 2019). Furthermore, the device is particularly suitable for real-time measurements compared to conventional and commercial ISEs, as it provides results in less than one minute and requires a small sample volume (< 30 milliliters). More than measuring nutrient solutions, the system analyzes ion proportions in plant leaf juice under different cultivation conditions and then utilizes various statistical methods to analyze the ion composition. The findings showed a correlation between the plant's internal ion status and physiological characteristics, health status, and quality (Huang et al., 2021).

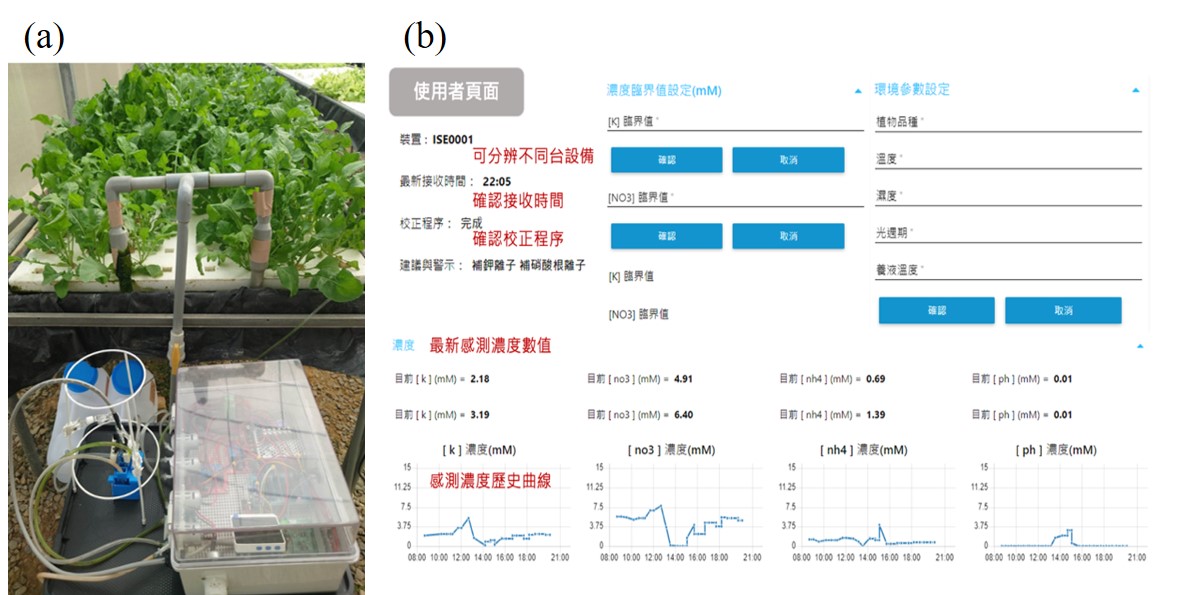

Figure 1.(a) Automated multi-ion sensing system (AMISS) installed in a greenhouse. (b)Real-time remote monitoring user interface.

Figure 1.(a) Automated multi-ion sensing system (AMISS) installed in a greenhouse. (b)Real-time remote monitoring user interface. In 2022, IoNSS was developed based on the portable multi-ion sensing device and integrated with Internet of Things (IoT) technology to achieve real-time remote monitoring of nutrient solution (Fig.1). IoNSS can simultaneously measure eight ion concentrations (nitrate, ammonium, potassium, calcium, sodium, chloride, magnesium ions, and pH value.) and operate automatically (Wu et al., 2023). In 2023, the system successfully completed several on-site verifications, which provided real-time monitoring of hydroponic nutrient solutions for crops such as arugula and lettuce for over two weeks. The results verified that the system possesses the following capabilities: 1. Applicability within both fully and semi-artificial farms, e.g., greenhouses and plant factories; 2. Detection of changes in ion changed trends consistent with both EC and pH values; 3. Capacity to discern changed proportions in ion concentrations across various nutrient solution formulations; 4. Consistency in measurements with errors less than 1 mM and high daily measurement repeatability; 5. Capacity to analyze differences in ion concentrations within crops cultivated under different nutrient formulations; 6. Capacity to investigate the correlation between potassium nitrate concentration in leaf juice and the corresponding fresh weight (Fig.2).

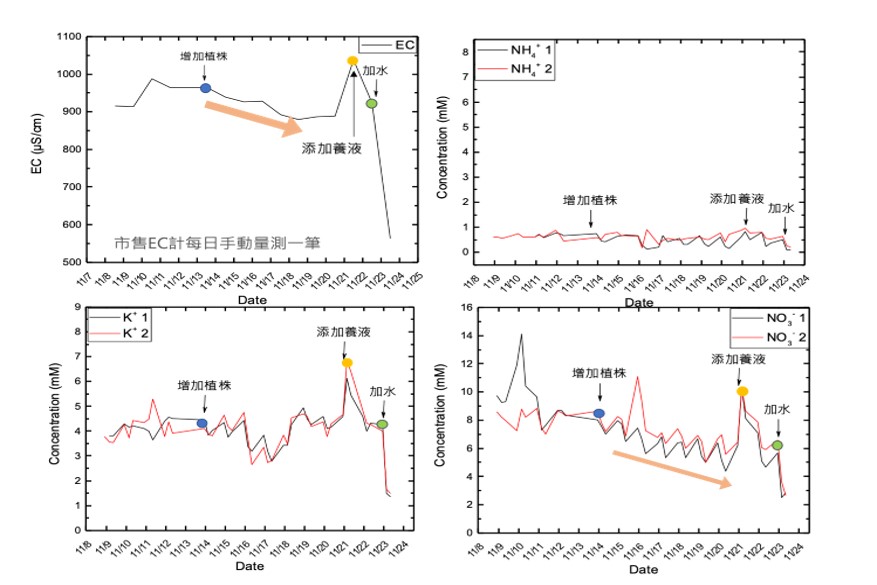

Figure 2. Ion concentration changes in the on-site monitoring. Year: 2022; location: hydroponic greenhouse, NPUST; nutrient solution used: Yamazaki nutrient solution

Figure 2. Ion concentration changes in the on-site monitoring. Year: 2022; location: hydroponic greenhouse, NPUST; nutrient solution used: Yamazaki nutrient solution Through long-term on-site monitoring, the ion concentration measures with IoNSS can serve as references for fertilizer supplementation. It can distinguish individual concentrations of potassium fertilizer, nitrate nitrogen fertilizer, and ammonia nitrogen fertilizer, as well as the uptake of divalent ions by crops. Therefore, changes in ion concentrations in the nutrient solution can be used to assess crop nutrient absorption. Furthermore, continuous monitoring of long-term ion variations in the nutrient solution, combined with environmental parameters such as temperature, humidity, and wind speed, will provide decision recommendations for facility control. This will allow for rapid adjustments to optimize cultivation conditions under varying climates.

Reference

陳林祈、姚傑文、陳志豪、張家豪 (2016)。中華名國專利號I517989。台北:經濟部智慧財產局。

陳林祈、鄭宗記、方煒、陳建彰、顏敬容、潘慶育、吳柏林、楊承翰、黃聖丰 、史唯里、吳伊敏、呂奇翰 (2019)。中華名國專利號I695166。台北:經濟部智慧財產局。

Huang, S. F., Shih, W. L., Chen, Y. Y., Wu, Y. M., & Chen, L. C. (2021). Ion composition profiling and pattern recognition of vegetable sap using a solid-contact ion-selective electrode array. Biosensors and Bioelectronics: X, 9, 100088.

Wu, Yi-Min and Liu, Shao-Yuan and Shi, Bo-You and Peng, Jui-Yu and Kao, Zhi-Wei and Chen, Yi-Yi and Hsieh, Ting-Yu and Chung, Hsing-Ying and Lin, Chi-Yi and Fang, Wei and Chen, Lin-Chi, Iot-Interfaced Solid-Contact Ion-Selective Electrodes for Cyber-Monitoring of Element-Specific Nutrient Information in Hydroponics. Available at SSRN: https://ssrn.com/abstract=4457369 or http://dx.doi.org/10.2139/ssrn.4457369

Research Funders

Ministry of Agriculture

Grant numbers: 111AS-8.3.2-ST-a3 and 112AS-13.1.4-ST-a3