Author:Professor An-Pan Cherng / National Ilan University

I. Introduction

Autonomous mobile robots are widely applied in agriculture. In particular, with the rapid development of information and communication technologies, academic research and commercial products with respect to miniaturized, multi-function or specialized robots as well as robots with high levels of intelligence have developed vigorously in recent years, which leads to fierce competition and rapid generational changes. In the livestock industry, advanced technologies can be introduced into the poultry farming sector by developing robots for poultry houses, further mitigating labor shortages, reducing human-animal contacts and the chances of animal disease transmission as well as assisting with daily duties in poultry houses and remote diagnosing. Moreover, data collected by robots helps improve the environment of poultry farming by creating a safe, hygienic friendly environment that facilitates animal welfare.

One of the main functions of robots in warehouse systems is transporting objects, and more diverse applications can be developed for agricultural uses, such as in livestock and poultry houses. For example, working robots equipped with power tools are developed in other countries. These working robots can deal with farm affairs, including spraying disinfectants, sorting bedding with rakes, turning bedding with rotary plough blades to facilitate the cleaning of poultry manure, deodorization and disinfection, picking up poultry eggs, and collecting dead poultry. International scholars also believe that the research in the past focused on the fields of monitoring and harvesting. In the future, the biggest challenge will relate to working robots for specific agricultural tasks, which is the driving force behind the development of agricultural robots.

II. Environment of Poultry Houses in Taiwan

Take the colored broilers in the poultry industry in Taiwan for example. Most chicken barns are rectangular buildings with approximately 100m in length and 15m in width, making them capable of housing about 10,000 chickens. Managers usually separate roosters and hens with fences about 80cm in height. In the chicken coop, feeder lines, water lines and other piping are installed along the longitudinal direction. The height of the piping is adjusted according to the age of the chickens, and the distance between the ends of the pipelines and the lateral walls in each coop varies. If the distance is too small, it may affect the turning space for the robots. Traditional chicken coops have upright pillars and horizontal beams at intervals of about 5 meters. The floor is covered with rice hulls as bedding, which can be over 10cm thick. Sometimes, the bedding may clump due to moisture or become depressed from prolonged trampling by people and chickens, which also affects the movement of the robots in poultry houses. In addition to fixed objects, chickens may be lying down, standing, or walking. Thus, the robots must be equipped with an obstacle avoidance function to prevent collisions with pillars, trough feeders, and other obstacles in the environment as well as chickens with unpredictable movements.

Fig.1. A photo of a robot patrolling autonomously in a chicken coop (I).

Fig.1. A photo of a robot patrolling autonomously in a chicken coop (I). Fig.2. A photo of a robot patrolling autonomously in a chicken coop (II).

Fig.2. A photo of a robot patrolling autonomously in a chicken coop (II). Fig.3. A photo of a robot patrolling autonomously in a chicken coop (III).

Fig.3. A photo of a robot patrolling autonomously in a chicken coop (III).III. Development of Robots for Poultry Houses

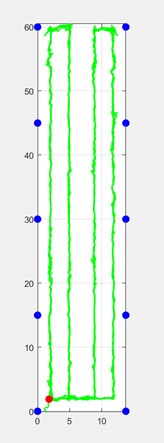

Fig.4. The cruising path of the robot

Fig.4. The cruising path of the robot

in the chicken coop.The cruising robot for poultry houses developed by our team is approximately 45cm in length and width, 25cm in height, and weighs about 10kg. It is equipped with four independently driven DC motors and deep tread tires, which allows it to easily patrol back and forth on the soft bedding in a chicken barn. Light detection and ranging (LiDAR), ultrasound, and laser distance sensors at different heights are installed on the robot. The robot is also equipped with cameras to observe the poultry house’s environment around its body as well as the condition of the chickens. This method - using multiple sensors to perform mutual verification on the returned data - provides a more robust obstacle avoidance function. With a battery life of over four hours, an ultra-wideband (UWB) indoor positioning system and obstacle avoidance functions, the cruising robot is able to patrol a chicken coop that is 100m in length and 15m in width several times continuously.

The cruising robot, serving as a multifunctional lightweight platform, is a working robot, and tasks for which can be just simple patrols. Since chickens are very sensitive, they can be motivated to stand up and move around during the patrol by using changes in sound and light nearby, even with the help of additional soft, long sticks. In addition, the cruising robot can also be equipped with environmental sensors (e.g., thermometers, hygrometers, etc.), cameras and other sensors to return real-time information on the environments of small areas in the poultry house and the health status of the chicken flock, thereby assisting in the management of poultry house affairs.

Fig.5. Interaction between chickens and the robot.

Fig.5. Interaction between chickens and the robot.IV. Conclusion

The cruising robot developed by our team already possesses the basic functions for cruising and data collection. In the future, we can try to extend the application to other kinds of poultry houses, such as those for ducks and geese. However, the introduction of new technologies results in the same issues both domestically and internationally. Despite the emergence of commercial products in the poultry industry in other countries, their widespread adoption is still limited, primarily due to the low level of acceptance among the operators. To implement the new intelligent technological tools in the industry, not only do the operators and developers need to engage in more conceptual dialogue to find a balance point that drives the progress, structural changes in poultry houses are also necessary to facilitate the autonomous operation of machines. Only with this can technology assist in industrial upgrade, thereby creating a new win-win situation for both humans and poultry.