Author:Cong-Chuan Pham/Ph.D Student, Department of Mechanical and Electromechanical Engineering, National Sun Yat-Sen University

Wei-Chih Lin/Distinguished Professor, Department of Mechanical and Electromechanical Engineering, National Sun Yat-Sen University

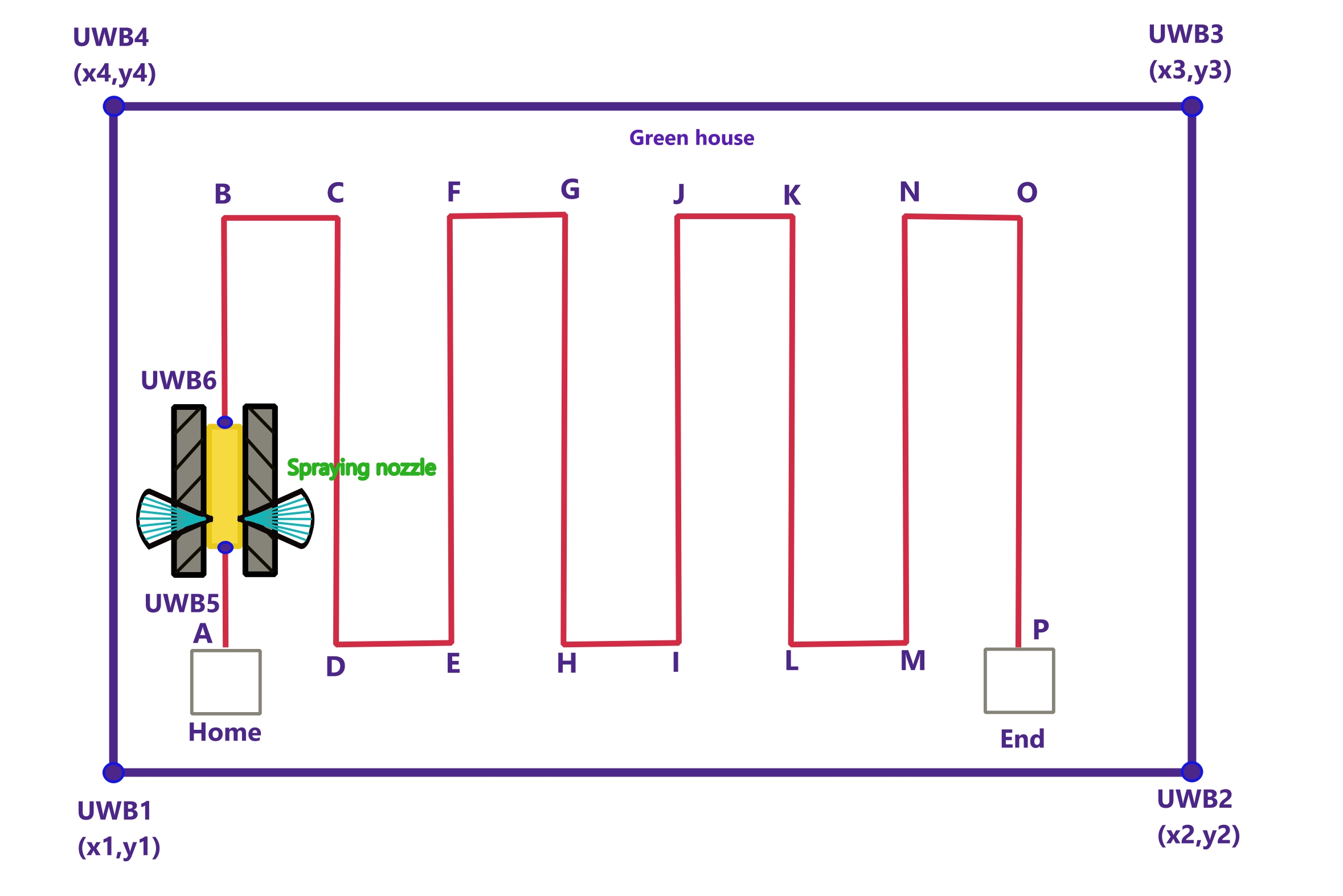

The spray truck uses the UWB module for precise positioning in the greenhouse. Positioning stations with known locations are fixed in the greenhouse, and two other modules are placed on the vehicle to determine the vehicle's location and direction of movement. The map data that stores the location information of the greenhouse needed for vehicle control will be saved in a file and automatically loaded at system startup. All data is processed through a Jetson-Nano computer .The vehicle performs spraying according to the route from the starting position to the ending position. The vehicle uses a level sensor to measure the amount of liquid remaining in the tank. If water or pesticides run out during spraying, the car will save that position and automatically return to the refill position to add more liquid. After charging enough pesticide, the vehicle returns to the previous post and continues until the entire greenhouse area is sprayed.

Figure 1: The working principle of UWB-based pesticide spraying vehicle

Figure 1: The working principle of UWB-based pesticide spraying vehicleThe test was conducted in the papaya garden in Liu-Gui Kaohsiung, Taiwan.

Figure 2: Vehicle testing in papaya greenhouse

Figure 2: Vehicle testing in papaya greenhouseAs a result, the vehicle can complete the spraying stably and move accurately in the greenhouse area of 32mx25m. Deviation from the center of the road is about ± 200 mm but still within the allowable range.

Figure 3: Running coordinate data

Figure 3: Running coordinate dataThe time to complete spraying the entire area is 13 minutes. Tests for the vehicle's battery life are also tested separately. The car can operate continuously for 2 hours. The safetyfunction that pauses when encountering an obstacle is tested and works correctly.

The research results demonstrate that developing an automated pesticide spraying vehicle for greenhouses using UWB technology offers a promising solution for precise and efficient pesticide spraying. Integrated UWB navigation, obstacle detection, and auto-return function ensure precise and uninterrupted spraying while reducing chemical use and minimizing farmer hazards. This advancement in greenhouse insecticide spraying technology has the potential to revolutionize agricultural practices, promote sustainable farming and enhance crop protection strategies.